In this case story we will look at a complete MDC and DNC solution installed recently at one of our customers. This case is a great example of how MDC is used to help optimize production processes and how DNC enables data communication on the shop floor.

Our customer’s manufacturing facility hosts four Hessapp machines and five Okuma machines setup to work as production lines. Workflow and production is highly optimized and efficient – not only because of their professional team of staff but also because they greatly benefit from a CIMCO DNC solution for NC program upload and download and a CIMCO MDC solution for automatic machine data collection that provides essential information, in real-time, about every machine on the shop floor.

The MDC & DNC solution has given our customer the following immediate benefits:

- Automatic and manual collection of machine data

- Real-time monitoring of all machines

- Real-time monitoring of machine, job and part status

- Real-time overview and information about the events on the shop floor

- Performance data for all manufacturing processes

- Identification of bottlenecks in production processes

- Less paperwork

- Unlimited manufacturing data history

- Accurate production data for further analyzing

Hardware and Software

For the CIMCO DNC & MDC solution the following hardware and software were installed:

Hardware

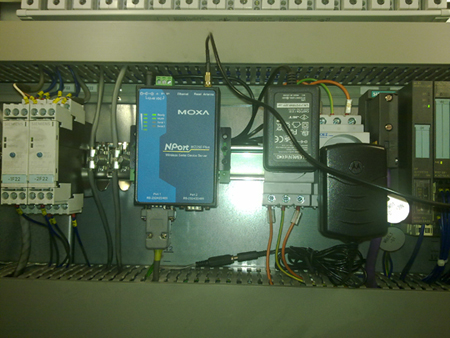

7 x Wireless Serial Servers – MOXA NPORT W2250 PLUS

For wirelessly connecting CNC machines and Barcode readers to the existing Ethernet network.

7 x Barcode Readers – MOTOROLA SYMBOL

For logging events on the shop floor by manually scanning barcodes associated with specific events at machines.

1 x Flat Screen TV – LG 47″ LCD with mini PC, Windows XP Home, HDMI connection and wall mount holder.

For showing real-time machine status and performance on the shop floor.

Software

1 x CIMCO DNC-Max Server running as service on Windows server 2008

For transferring (upload/download) NC programs between machines and PCs.

1 x Backup service set to backup everything once a day

For securing critical production data in case of break-downs.

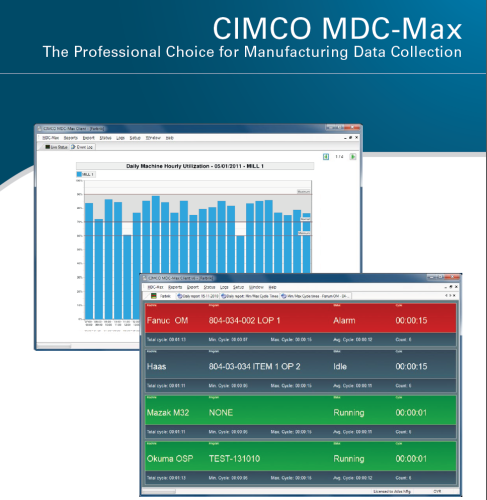

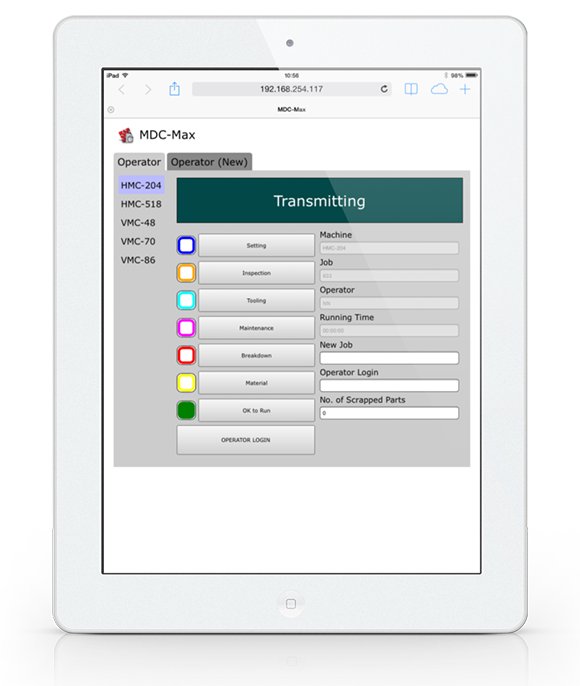

5 x CIMCO MDC-Max client with floating licenses

For running CIMCO MDC-Max on staff PCs and the Flat Screen TV.

Used by:

- Production Manager

- Shop floor Manager

- Inspectors

- Setters

- Flat Screen TV

![Flat screen TV on the shop floor - placed where everyone can see it. Flat screen TV on the shop floor - placed where everyone can see it.]()

Flat screen TV on the shop floor – placed where everyone can see it.

![Barcodes at a machine - for manually logging events with barcode reader. Barcodes at a machine - for manually logging events with barcode reader.]()

Barcodes at a machine – for manually logging events with barcode reader.

![Wireless Serial Server installation at machine. Wireless Serial Server installation at machine.]()

Wireless Serial Server installation at machine.

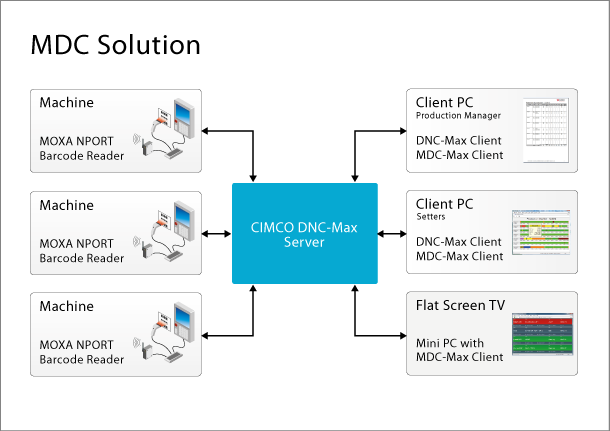

Overview of CIMCO MDC solution

The image below shows a diagram of the CIMCO MDC solution.

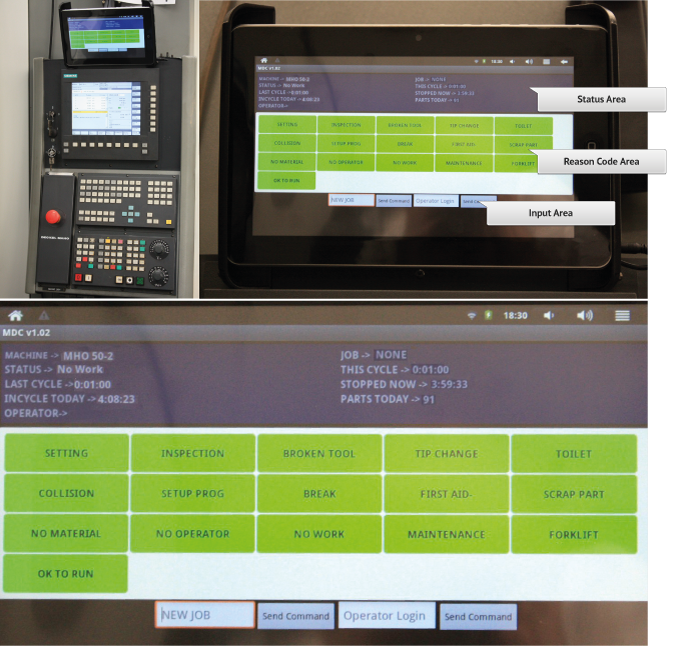

On the left side the machines on the shop floor are equipped with Wireless Serial Servers for network connectivity and Barcode readers for logging and sending back information about events at the machines.

On the right side are the client-PCs with CIMCO MDC-Max installed. The Production Manager uses CIMCO MDC-Max to get reports on production statistics. Setters use CIMCO MDC-Max to see timeline graphs showing performance and activity for every machine. The Flat Screen TV on the shop floor shows the current status of all machines. Everyone can see the TV and act on its real-time updates such as when a machine stops for part reloading or is down for maintenance.

In the center a server with CIMCO DNC-Max Server is responsible for storing and transferring production data between machines, Barcode readers and the client PCs. It is the core of the MDC solution and is scalable in terms of later expanding the setup to support more machines and client PCs.

![Diagram of the CIMCO MDC solution. Diagram of the CIMCO MDC solution.]()

Diagram of the CIMCO MDC solution.

Gathering information from the shop floor

Production data is gathered from the shop floor both automatically and manually. Automatic data is sent directly from machines and manual data is sent whenever a member of staff scans a barcode to signify an event.

As part of the installation all CNC machines were configured to send back data on three events:

- PROGRAM IS RUNNING

- SPINDLE IS RUNNING

- PART COUNT

When these events are detected on a machine it transfers that data back to CIMCO MDC-Max.

Each CNC machine in the installation is also equipped with a Barcode reader for manual data collection. Barcode readers are used by Operators, Setters and other staff members on the shop floor to log events about their operation at a machine such as JOB START, SETTING STOP, MAINTENANCE, etc.

Logging an event is simply done by scanning a barcode associated with a specific event and verifying, by looking at the flat screen TV, that the MDC system has received the event and updated the machine’s status correctly.

For this installation the following barcodes were set up:

- JOB START + job number

- JOBSTOP

- SETTING + name of setter

- SETTING STOP

- INSPECTION + name of inspector

- INSPECTION STOP

- OPERATORLOGIN + name of operator

- OPERATORLOGOFF

- MAINTENANCE + name of technicians

- MAINTENANCE STOP

- SETTING SCRAP

- DRILLING SCRAP

- PRODUCTION SCRAP

- MATERIAL SCRAP

- DRILL FAILLURE

- MEASURING FAILURE

- TURNING FAILURE

- NO CAST

- UNSPECIFIED FAILURE

CIMCO MDC-Max handles all the data that is gathered and presents it in a structured and accessible manner. Some data is sent in real-time to the Flat Screen TV on the shop floor and other data is shown in e.g. timeline graphs on client PCs or exported as detailed reports including Overall Equipment Effectiveness (OEE).

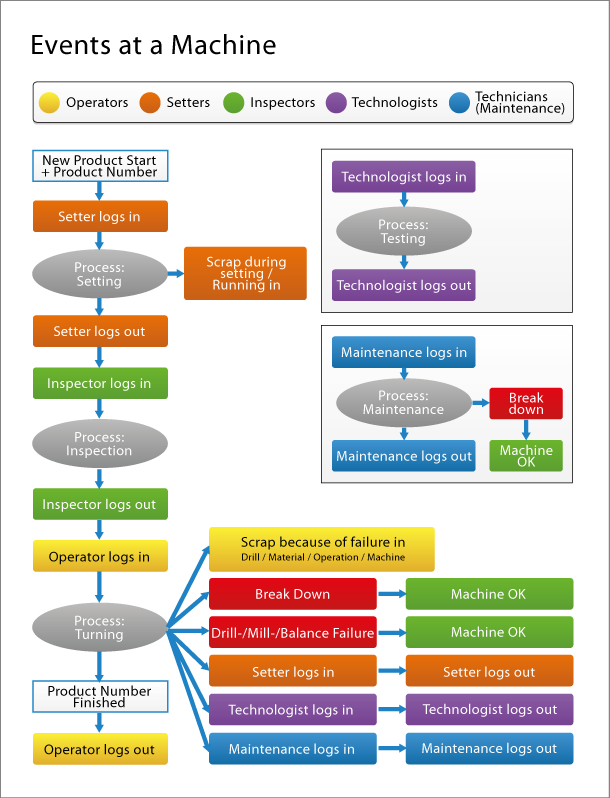

The following diagram shows the processes and events involved at one of the machines in the setup. Many of these events are logged and enable CIMCO MDC-Max to generate detailed statistics on each of the processes. This gives a good overview and helps identify bottlenecks.

In the diagram the following staff members are involved in the processes:

- Operators

- Setters

- Inspectors

- Technologists

- Technicians (Maintenance)

![Events at a Machine Events at a Machine]()

Events at a Machine

The daily usage of the CIMCO MDC solution

At our customer it has now become a daily routine to generate reports on:

- Statement of production

- Overview of shifts performances

- Performance of setters

- Performance of inspectors

- Performance of maintenance

- Planning and bonuses

![Reports can be generated and exported to Microsoft Excel. Reports can be generated and exported to Microsoft Excel.]()

Reports can be generated and exported to Microsoft Excel.

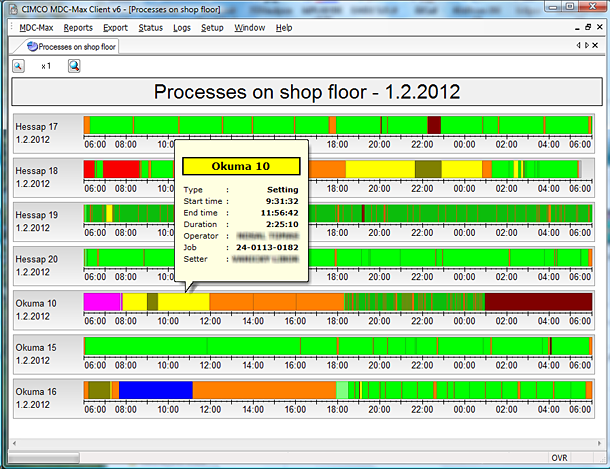

CIMCO MDC-Max is further used for the following:

- Shows real-time monitoring of CNC machine on PCs

- Shows real-time monitoring on Flat Screen TV on the shop floor

- Shop floor Manager and Setters get timeline graphs for every machine

- Inspectors easily indicate scrapped parts with a user-configured button in CIMCO MDC-Max.

![Timeline graphs for each machine on the shop floor Timeline graphs for each machine on the shop floor]()

Timeline graphs for each machine on the shop floor

The CIMCO DNC & MDC solution has provided our customer with a powerful tool to help them optimize and monitor their day-to-day production. A solution that, according to our customer, has resulted in an increase in productivity.

If you have not visited our site recently, you might notice some big changes here. You will find a walk through the history of what led to these changes on the

If you have not visited our site recently, you might notice some big changes here. You will find a walk through the history of what led to these changes on the